In a fully-continuous production process, each product needs to be precisely positioned, to prevent it from being lasered or labelled incorrectly.

To achieve this, the entire assembly line is equipped with cameras for part and position detection. These cameras communicate with the assembly line to ensure everything is in tune and the marking process runs seamlessly. The laser communicates with the cameras and vice versa to configure itself correctly.

As far as the marking process is concerned, we refer to both laser marking and label marking. In both cases, the mark must be placed precisely in the right place. Camera integration makes sure that this is carried out correctly.

Prolaso has experience with different camera suppliers like Cognex, Trumpf and Keyence.

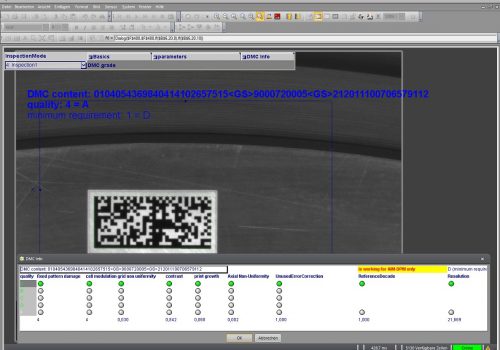

The cameras are also used for product verification. A marked DMC code has to be verified and, if the camera allows it, also has to be assessed for quality (grading process).

Send us an inquiry or speak to our Prolaso customer service today. Explore our different solutions.

We are available 24/7.